Construction forklifts and telehandlers

Storage and load-handling solutions: what you will find in our forklift truck shop. They are the undisputed inhabitants of logistics, automated warehouses and construction sites. Indispensable in warehousing, loading/unloading goods, handling and transport activities. They are essential tools for simplifying daily activities in many sectors, including construction, industrial, commercial, plant engineering and many others.

Forklifts

In our forklift truck shop, you will find machines that differ in structure, power supply or intended use. In particular, you can choose from:

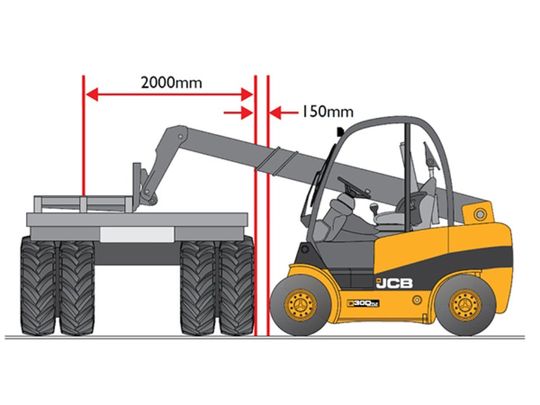

Telescopic handlers

Telescopic handlers are forklifts equipped with telescopic arms that are particularly suitable for civil and industrial construction and agriculture. They fall into two categories:

Fixed towers: they can only lift loads from the front;

Rotating towers: they are fitted with a rotating cab that allows them to operate easily even in awkward or narrow job sites. They are often equipped with remote control systems.

How to choose the right trolley for your needs?

There are several parameters to consider when choosing the most suitable forklift for your needs:

- type of vehicle;

- maximum height reached by the mast system;

- width of aisles in case you need a forklift for the warehouse;

- power supply and operating system.

Contact us for more information

Contact our sales outlet for forklifts and telehandlers, forklift trucks, pallet trucks, for more information or to speak with a consultant.

HEADQUARTERS

Via Francesco Domenico Guerrazzi 3 42124 Reggio Emilia

Via Pignedoli 1/B

42035 Felina (RE)

TELEPHONE

Contact us to learn more about our forklift trucks